Last year, we enthusiastically took part in the “Die Casting in the Classroom” project, promoted by the Perlasca Institute of Vobarno, with the aim of introducing students of the Mechanics, Mechatronics and Energy course to the die-casting supply chain and the professional opportunities offered by our region.

Together with other local companies involved in steel supply and foundry production, we shared our experience and expertise with the classes, contributing to the development of a structured training program including multiple in-class lessons, a company visit, and a final test.

Throughout the project, we guided the students on a hands-on journey into the world of aluminum die casting, covering the main technical and organizational aspects that define our daily work.

1st Day – From Customer Request to Mold Design

We presented a real work scenario: a foundry entrusts us with the construction of a mold for producing an automotive component through die casting. Starting from this practical case, we explained how part feasibility is analyzed, the key stages of mold design, and how filling and solidification simulations help predict metal behavior and optimize part quality.

2nd Day – Mold Sizing and Construction

We introduced the basic concepts of mechanical design needed to understand the sizing, structure, and operation of a die-casting mold.

We then described the production process for building the mold: from steel procurement to machining, assembly, and final testing

3rd Day – Materials and Heat Treatments

In this lesson, led together with our partner specialized in tool-steel selection and supply, students learned about hot-work tool steels, including their classification, production cycle, and main mechanical and physical properties.

We also examined the heat treatments used on molds: from bulk treatments such as annealing, stress relieving and hardening, to thermochemical diffusion treatments — nitriding, oxidation, and carburizing — all essential for ensuring durability and long-term performance.

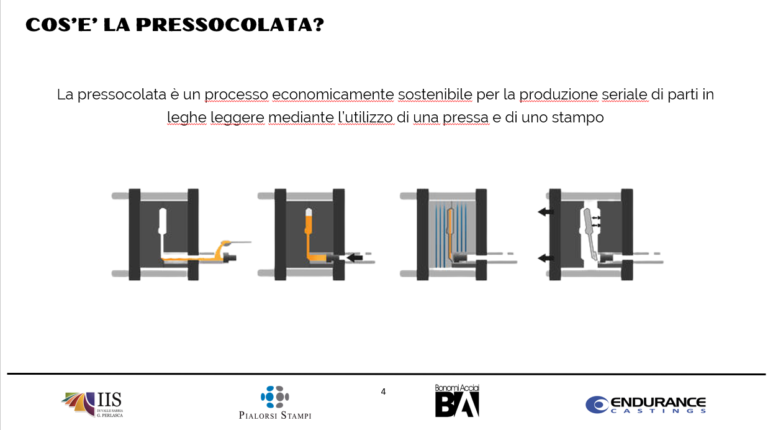

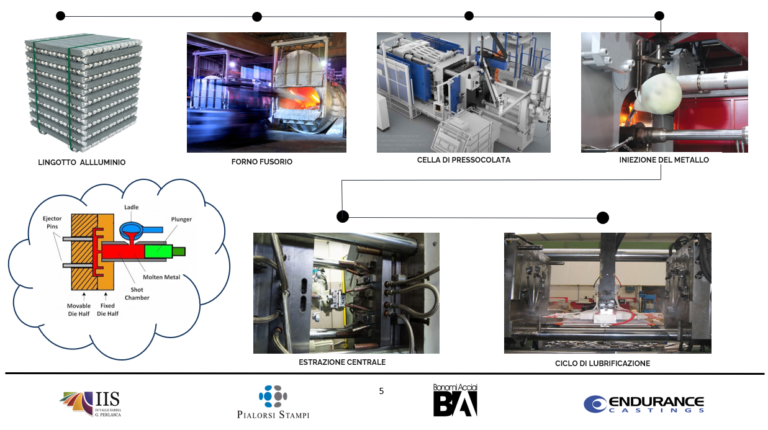

4th Day – The Production Chain and Part Quality

During the final session, held with the foundry, we offered an overview of the entire die-casting supply chain, from mold design to finished part production.

Students observed how a die-casting cell is set up, learned how it operates, and analyzed the quality factors that determine the success of a die-cast component.

The program concluded with a foundry visit and a final test, confirming the commitment and interest shown by the students throughout the course.

For us at Pialorsi Stampi, it was an extremely positive experience: an opportunity to share our work, meet young people, and help build a concrete bridge between school and industry.

We firmly believe that initiatives like this are an investment in the future of mechanics and die casting — a way to pass on knowledge, passion and curiosity to the new generations who may become the professionals of tomorrow.