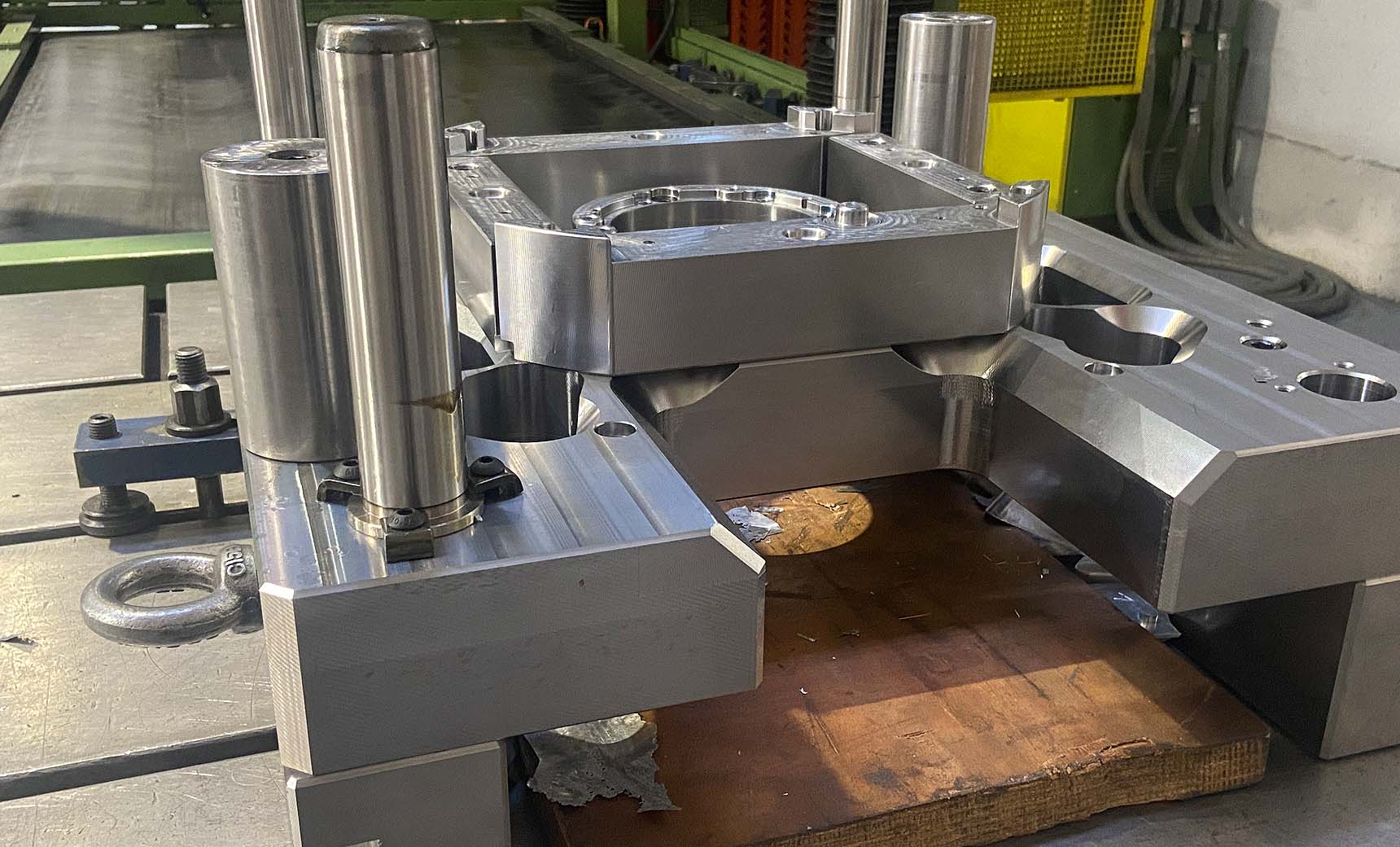

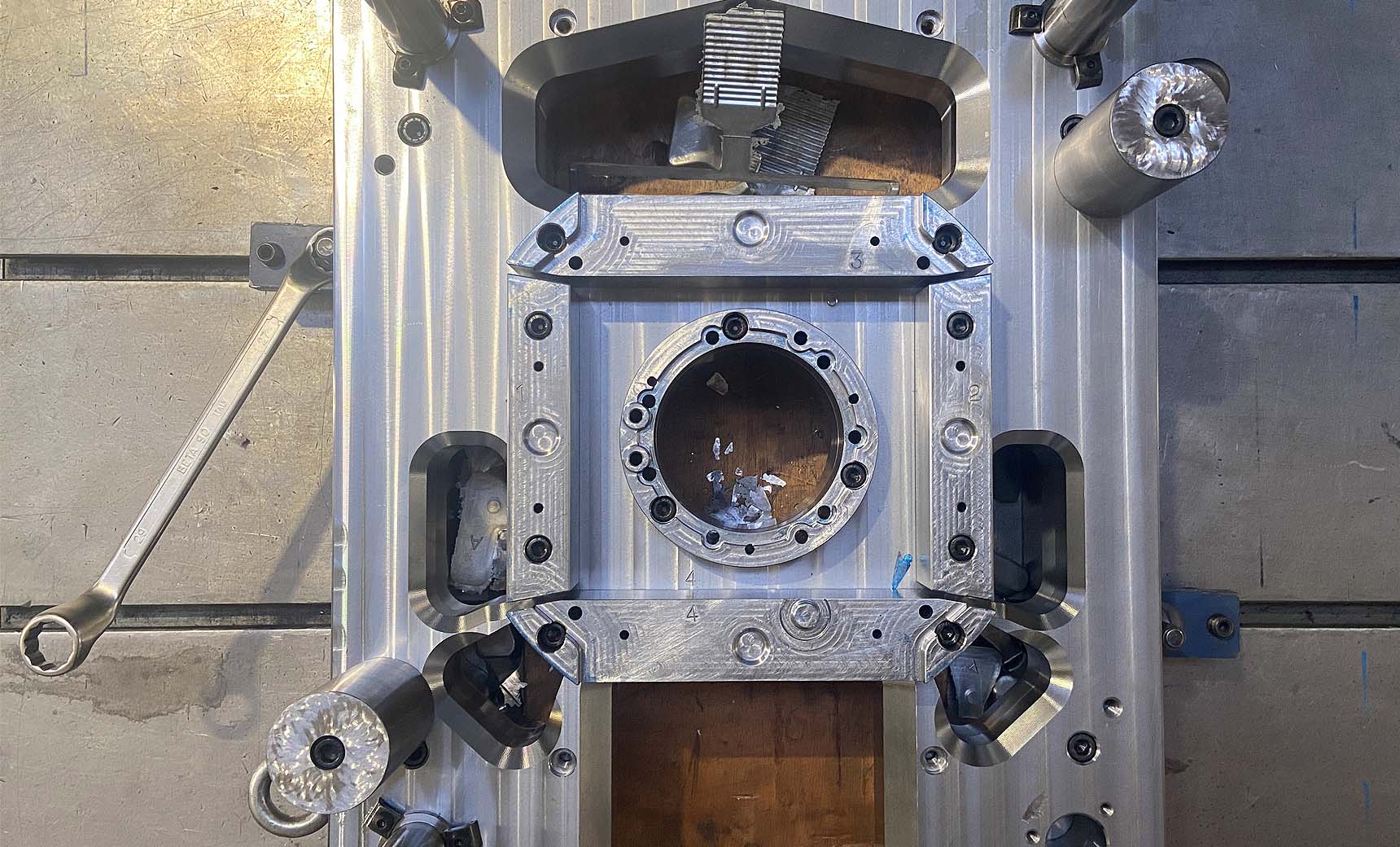

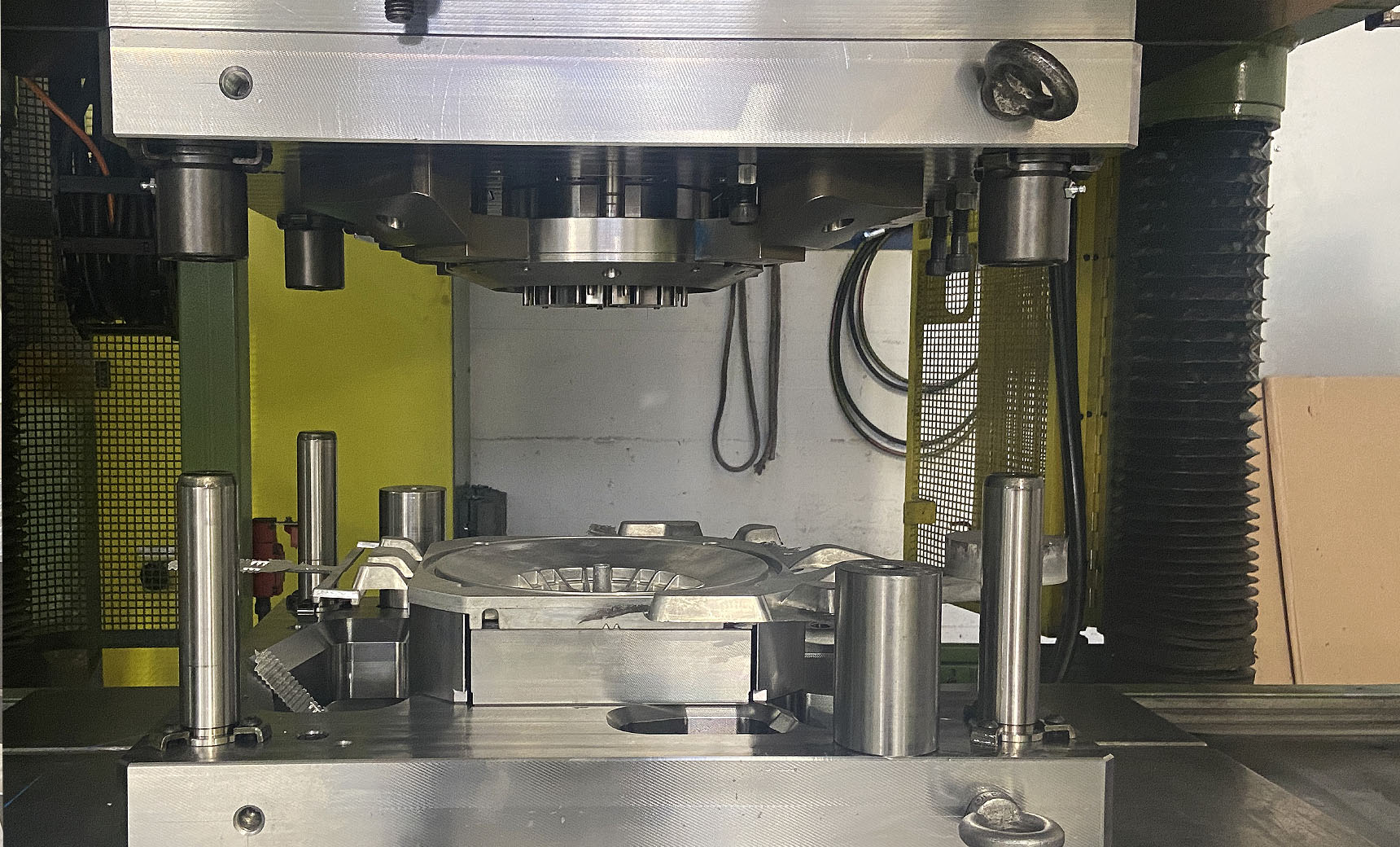

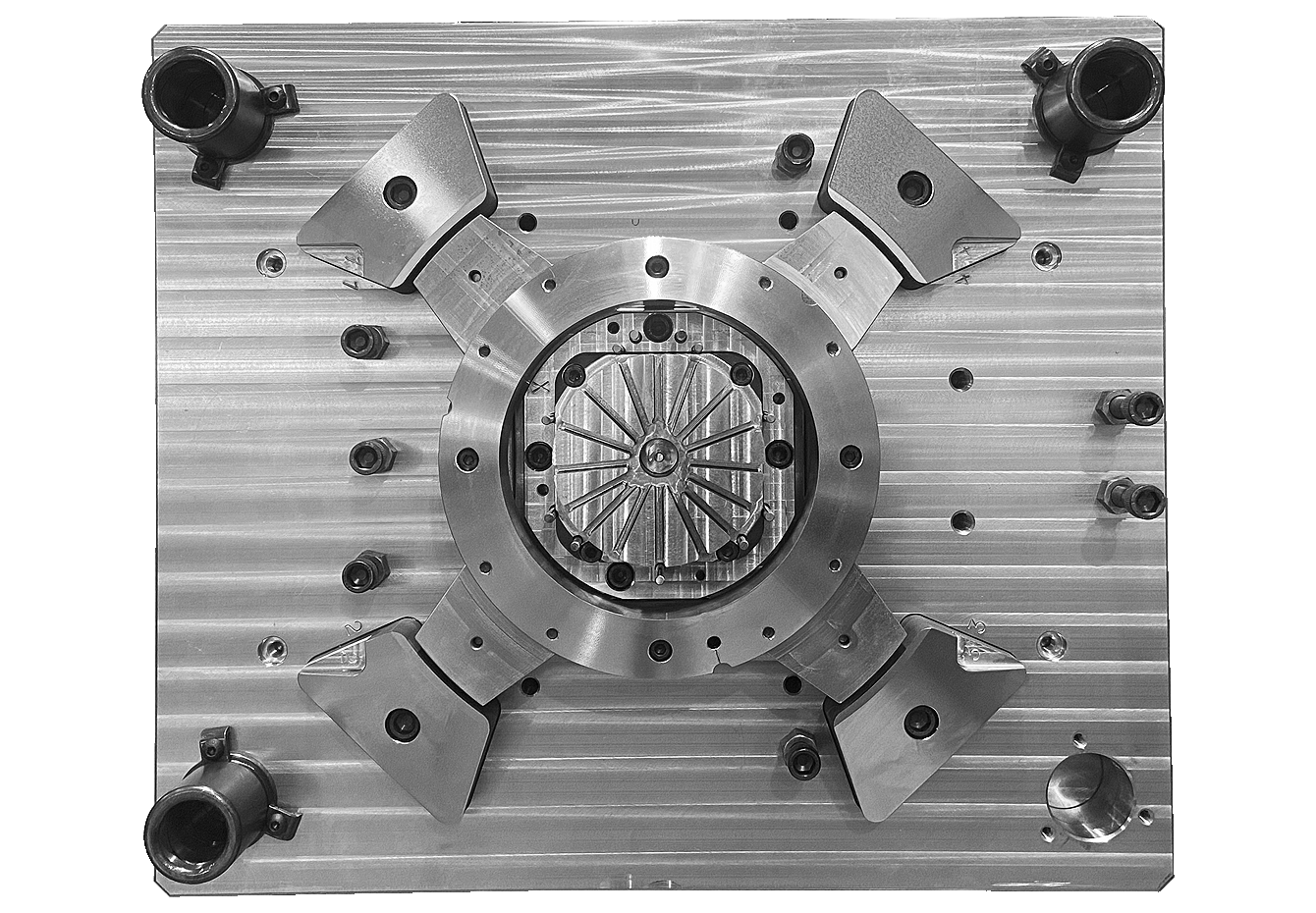

The deburring mould has the function to clean the die-casted parts from the so-called “sprue” and the through holes at the end of the die-casting process. It can also have a cutting area and a drilling area. In this way it is used in place of manual operations, to reduce costs and decrease the interruption of production cycle.

PRODUCTION DEBURRING MOULDS

Deburring moulds

We produce deburring moulds from the most simple to the more complex ones, working together with our reliable partners that are specialized in the design and production of this type of mold.