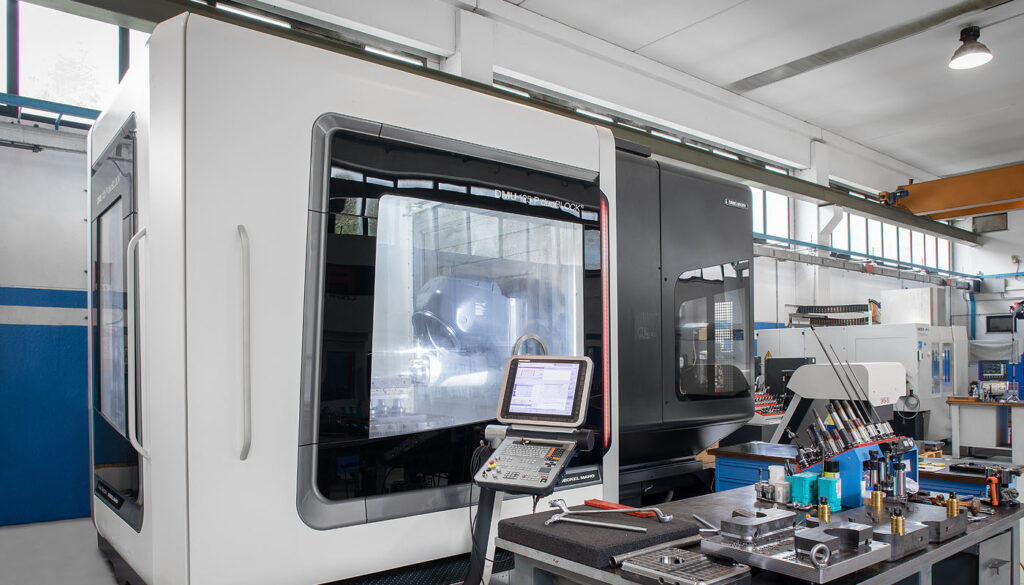

What has been analysed and designed in the technical office comes to life in our production department: the place where the ideas and the technical drawing are realized.

In the last few years, the production department went through a remarkable development: we have state-of-the-art machines and technologies aimed to bring both qualitative and economic advantages. We are aware of the ongoing evolution of the market, and this is way we keep updating our competences and equipment, to always keep up with the times.