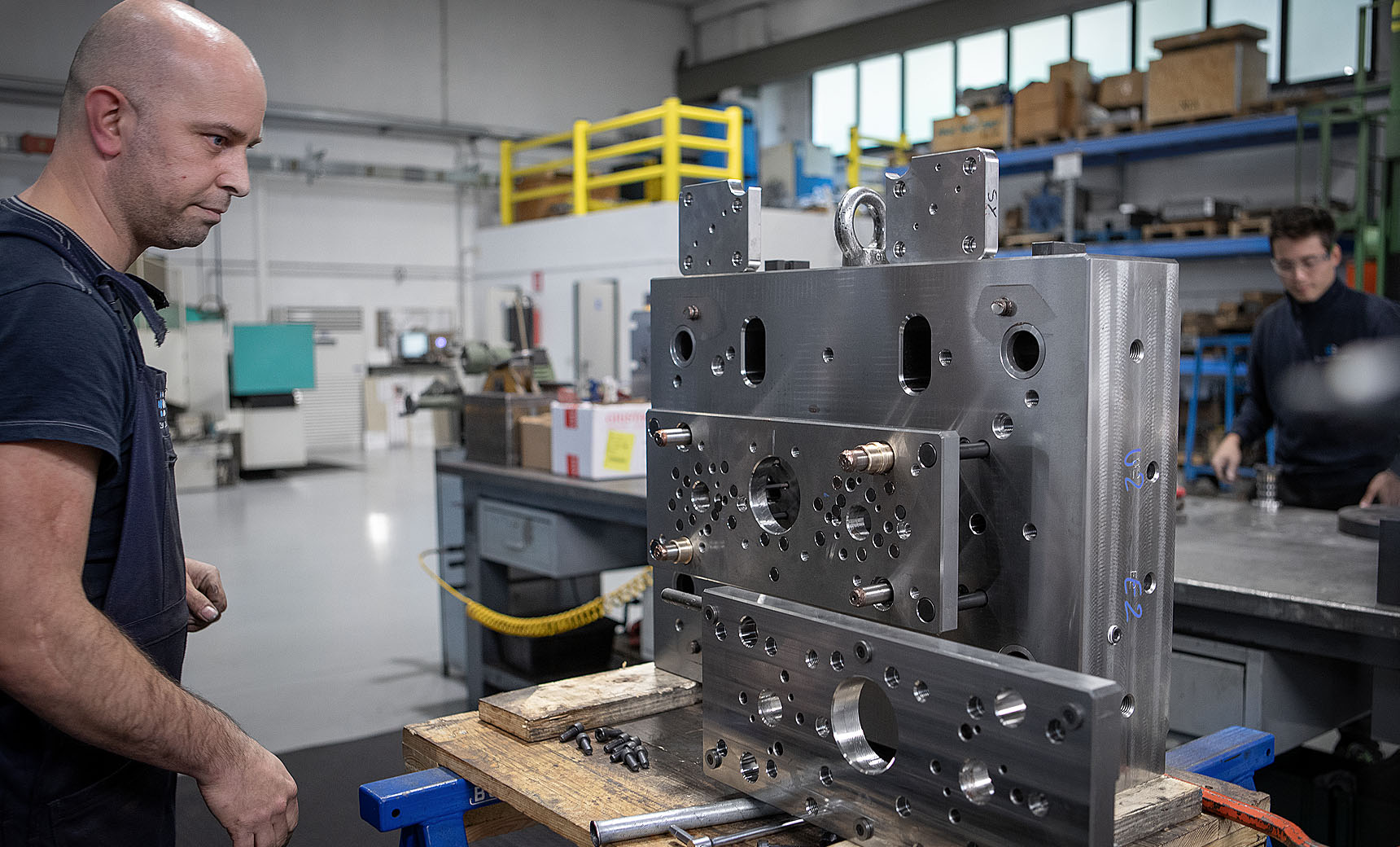

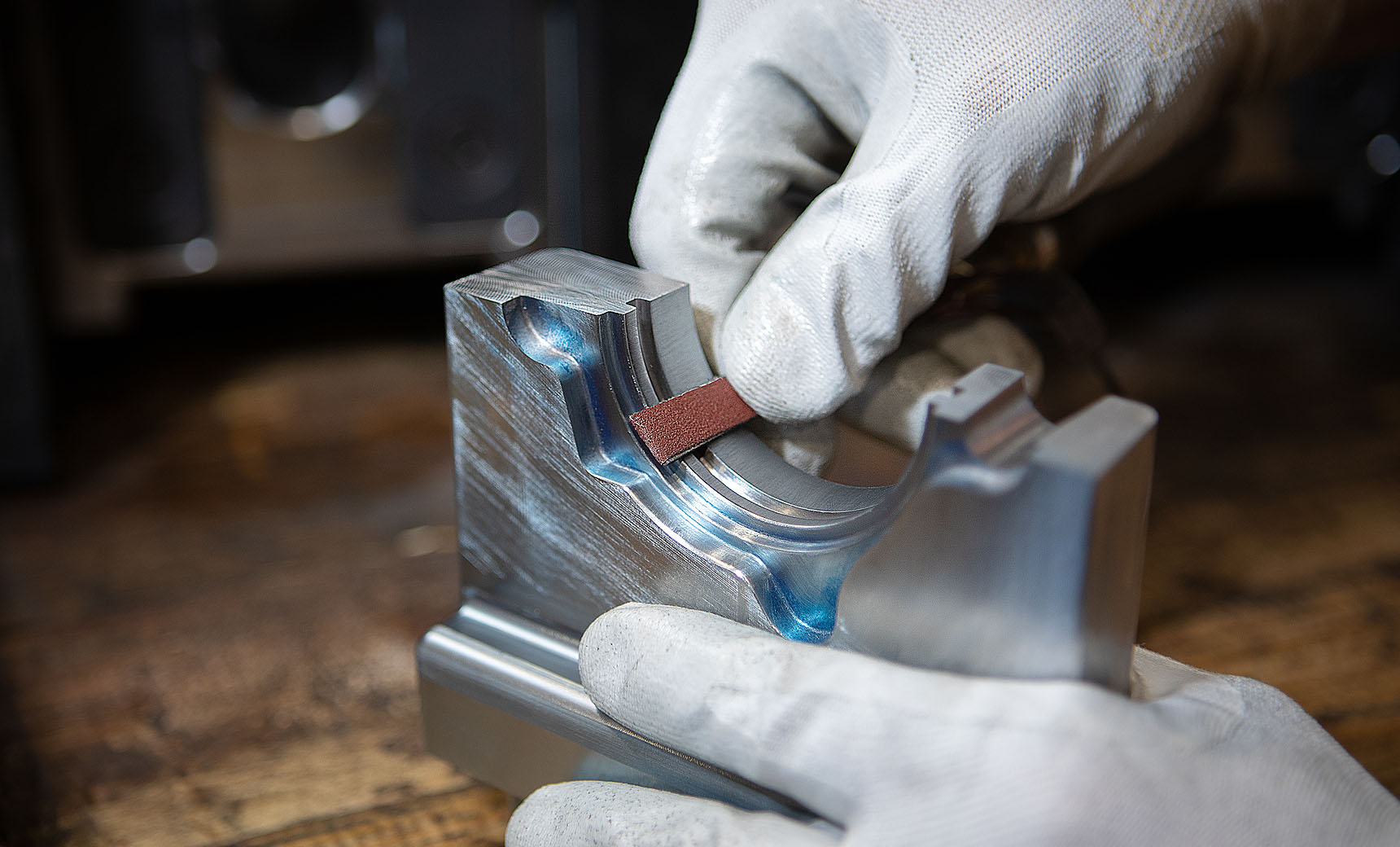

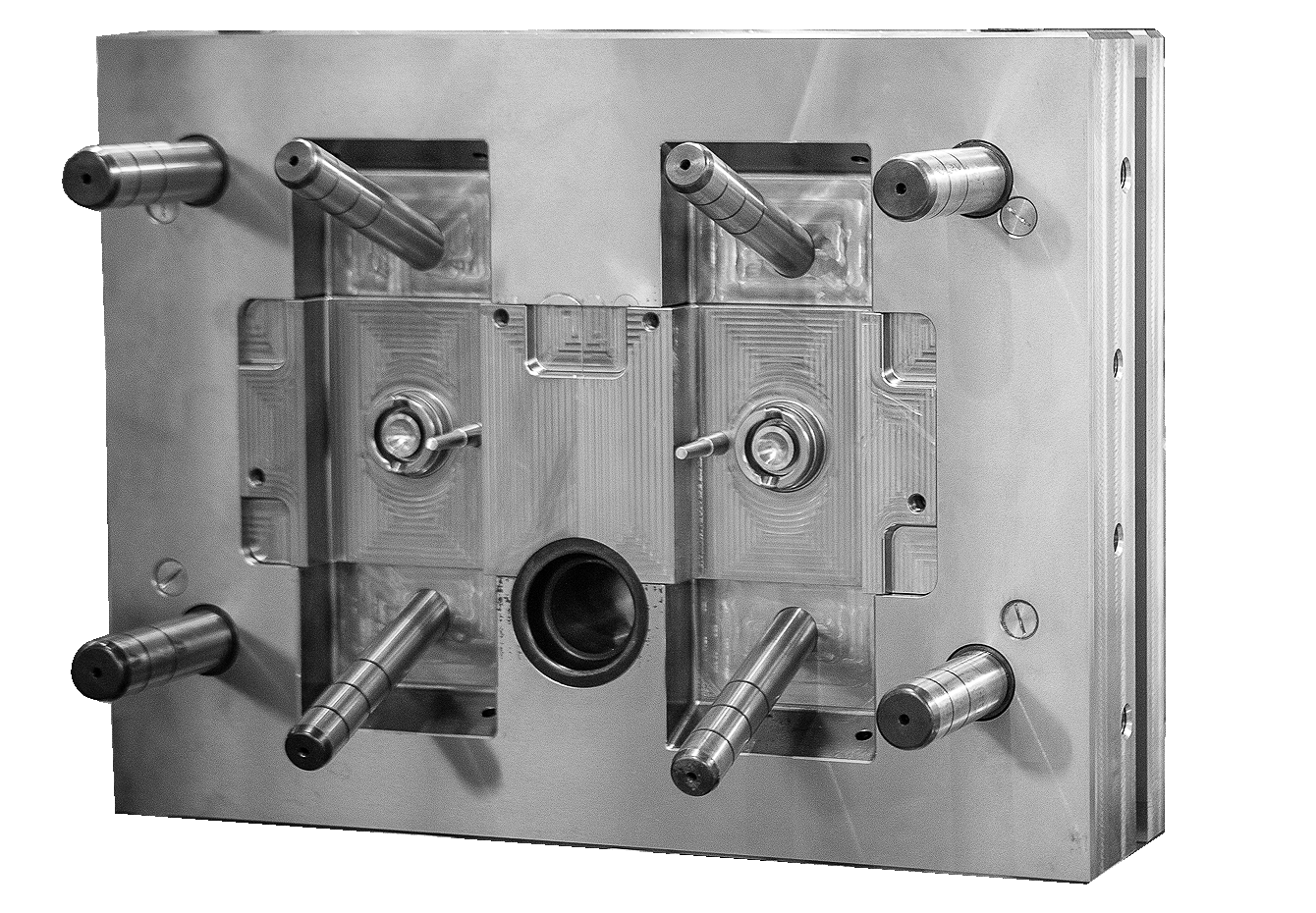

Aluminium die-casting moulds are subject to wear. The accurate design and the selection of the most suitable steel are certainly important factors that extend their life. But every mold need maintenance and adjustment during their productive process. The maintenance department handles directly this phase.

MAINTENANCE AND ADJUSTMENT OF MOULDS

MOULDS’ MAINTENANCE

Thanks to our internal mechanical workshop we do interventions of ordinary maintenance on the tools and possible fixings to guarantee a better performance over time. In the die-casting sector the productivity and efficiency are indeed fundamental to realize high-quality products in the shortest possible time.