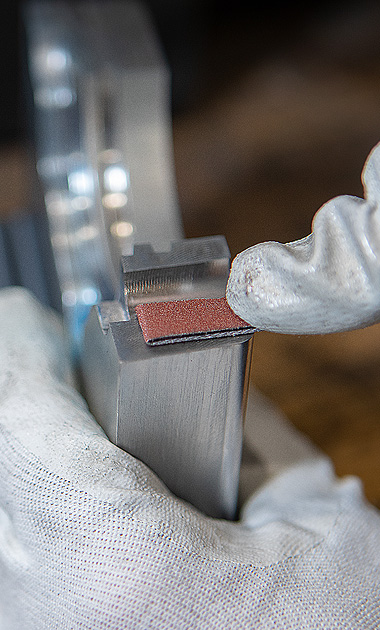

Pialorsi Stampi has dealt with the design and production of molds for aluminium die-casting for 60 years. The precise working method and the attention to details have given to the co-workers the experience necessary to start every single project with a high level of quality and professionalism.

DIE-CASTING MOLDS BRESCIA, PIALORSI, CUTTING-EDGE TECHNOLOGY

US, TRADITION AND INNOVATION IN MOULDS

We look after and support our clients since the very beginning: not only we take over the management of the required project, but we also make our long-time experience available as well as our competences updated through training courses with reliable external partners. We take responsibility to ensure that our clients achieve their own goals flanked by a professional team and guaranteeing quality and security.

We start from the basic concept, we evaluate the characteristics and the necessities required, by taking into consideration the economic costs, to come to a possible result of the new product. This can be possible also thanks to the experience in different industrial fields of which we are reliable partners.

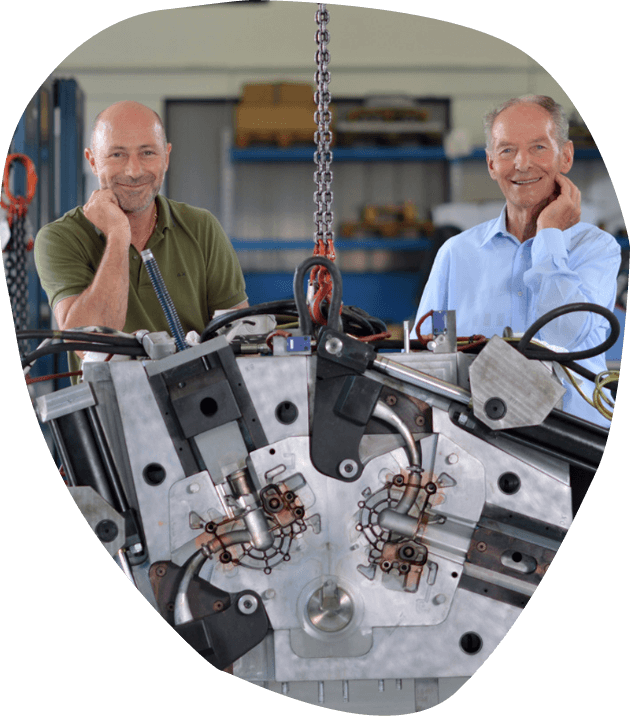

Tradition, innovation and passion.

Culture of doing, listening and learning.

One family, 3 generations and a single vision of the future.

“Grow and develop our company according to the principles at the basis of our doing. Grow and work in an healthy, stimulating and comfortable environment for all our collaborators.

Grow with respect for the surrounding environment and the working context, paying attention to waste, to the resources used and to everyone’s safety.”

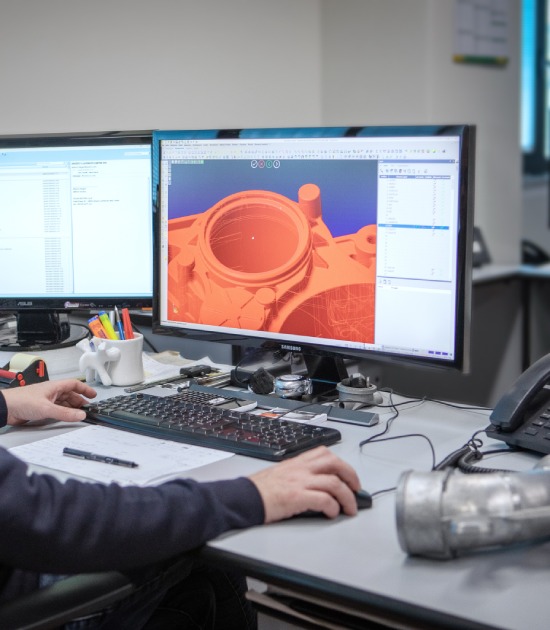

We create the first idea in an efficient and effective way: we study the feasibility and design at best the final product. We rely on an engineering process to identify the best solutions both functional and aesthetic to produce the final product. This operation realizes molds that reproduce the characteristics required, based on the type of item.

Out technical team’s competence is supported by filling simulation tools as well. They have indeed an important role during the design of high-performance moulds manufactured in our production and assembly departments, provided with cutting-edge 4, 5 and 6 axis machines, handled by CAM software.

Company video

Watch a 2-minutes video to see our team working in the different sectors of the company.